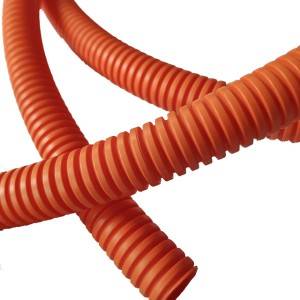

Polyamide Corrugated Tubing

Introductio Polyamide 6 Tubingae

Nylon tubing (polyamide), ad PA Tubing. Est quaedam fibra synthetica, cum bonis proprietatibus physicis et chemicis et mechanicis: resistentia abrasionis, in conditione arenae, micis ferreis adhiberi potest; lenis superficies, resistentiam minuere, rubiginem et squamam impedire potest; mollis, facilis, curvus, facilis, inauguratus et facilis ad processum. Eodem tempore ferrum est. Cum aliqua figura opus est, fieri potest in varias formas sicut tubus metallicus, nec eget perplexa instrumenta et instrumentum; Erugo multarum substantiarum chemicorum sustinere potest; stabilitatem habet et parvam permeabilitatem; Insulator adhiberi potest; vita servitus longissima, etiam decenniis; resistentia temperatura bona, operari potest in ambitu -40-115 °C.

WYK-PA6

| Materia | Polyamide 6 |

| Color | Gray (RAL 7037), nigrum (RAL 9005) |

| Temperature Range | Min-40℃,Max115℃,Short-term150℃ |

| Retardantia flammea | HB (UL94), secundum FMVSS 302: <100mm/min |

| Properties | Lenta et praeclara tenacitas, paries crassitudinis mediae, nitidumSuperficies, venti resistentes, vires mechanicae altae, repugnant oleo, acido et alcali. Anti-friction, nigrum Tubingae repugnant UV, Free Halogen, phosphoro et cadmia, transierunt RoHS. Ultra plana interior foramen, minus abrasio ad retinacula |

| Applications | Mechanica aedificium, electricum tutelae velit, sub terra, electricum vehiculum et aer-conditionalis apparatum etc.Maxime apta vehiculum industria crebris vibrationibus |

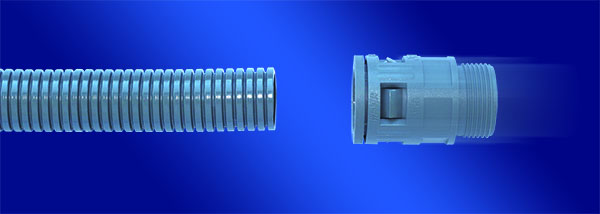

| fit cum | Omnes connexiones Tubing praeter WYTC apertum connexiones |

Tech Specification

| Articulus nullus. | Color | ID×OD | Stat.R | Dyn.R | Pondus | PU |

| WY-UFW-PA | G/B | mm×mm) | (mm) | (mm) | (kg/m±10%) | (m/anulum) |

| *WY-UFW-PA6-AD8.0G | Gray | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| *WY-UFW-PA6-AD10.0G | Gray | 6.5×10.0 | 15 | 35 | 0.018 | 100 |

| WY-UFW-PA6-AD13.0G | Gray | 9.2×13.0 | 20 | 45 | 0.022 | 100 |

| WY-UFW-PA6-AD15.8G | Gray | 12.0×15.8 | 25 | 55 | 0.093 | 100 |

| WY-UFW-PA6-AD18.5G | Gray | 14.3×18.5 | 35 | 65 | 0.041 | 50 |

| WY-UFW-PA6-AD21.2G | Gray | 16.0×21.2 | 40 | 75 | 0.05 | 50 |

| WY-UFW-PA6-AD25.5G | Gray | 19.5×25.5 | 42 | 85 | 0.093 | 50 |

| WY-UFW-PA6-AD28.5G | Gray | 22.2×28.5 | 45 | 100 | 0.093 | 50 |

| WY-UFW-PA6-AD31.5G | Gray | 25.0×31.5 | 50 | 110 | 0.093 | 25 |

| *WY-UFW-PA6-AD34.5G | Gray | 29.0×34.5 | 55 | 120 | 0.103 | 25 |

| *WY-UFW-PA6-AD42.5G | Gray | 36.0×42.5 | 65 | 150 | 0.153 | 25 |

| *WY-UFW-PA6-AD54.5G | Gray | 48.0×54.5 | 80 | 190 | 0.209 | 25 |

| WY-UFW-PA6-AD8.0B | Niger | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-UFW-PA6-AD10.0B | Niger | 6.5×10.0 | 15 | 35 | 0.018 | 100 |

| WY-UFW-PA6-AD13.0B | Niger | 9.2×13.0 | 20 | 45 | 0.022 | 100 |

| WY-UFW-PA6-AD15.8B | Niger | 12.0×15.8 | 25 | 55 | 0.093 | 100 |

| WY-UFW-PA6-AD18.5B | Niger | 14.3×18.5 | 35 | 65 | 0.041 | 50 |

| WY-UFW-PA6-AD21.2B | Niger | 16.0×21.2 | 40 | 75 | 0.05 | 50 |

| WY-UFW-PA6-AD25.5B | Niger | 19.5×25.5 | 42 | 85 | 0.093 | 50 |

| WY-UFW-PA6-AD28.5B | Niger | 22.2×28.5 | 45 | 100 | 0.093 | 50 |

| WY-UFW-PA6-AD31.5B | Niger | 25.0×31.5 | 50 | 110 | 0.093 | 25 |

| WY-UFW-PA6-AD34.5B | Niger | 29.0×34.5 | 55 | 120 | 0.103 | 25 |

| WY-UFW-PA6-AD42.5B | Niger | 36.0×42.5 | 65 | 150 | 0.153 | 25 |

| WY-UFW-PA6-AD54.5B | Niger | 48.0×54.5 | 80 | 190 | 0.209 | 25 |

| WY-UFW-PA6/S-AD8.0B | Slit Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-UFW-PA6/S-AD10.0B | Slit Black | 6.5×10.0 | 15 | 35 | 0.018 | 100 |

| WY-UFW-PA6/S-AD13.0B | Slit Black | 9.2×13.0 | 20 | 45 | 0.022 | 100 |

| WY-UFW-PA6/S-AD15.8B | Slit Black | 12.0×15.8 | 25 | 55 | 0.093 | 100 |

| WY-UFW-PA6/S-AD18.5B | Slit Black | 14.3×18.5 | 35 | 65 | 0.041 | 50 |

| WY-UFW-PA6/S-AD21.2B | Slit Black | 16.0×21.2 | 40 | 75 | 0.05 | 50 |

| WY-UFW-PA6/S-AD25.5B | Slit Black | 19.5×25.5 | 42 | 85 | 0.093 | 50 |

| WY-UFW-PA6/S-AD28.5B | Slit Black | 22.2×28.5 | 45 | 100 | 0.093 | 50 |

| WY-UFW-PA6/S-AD31.5B | Slit Black | 25.0×31.5 | 50 | 110 | 0.093 | 25 |

| WY-UFW-PA6/S-AD34.5B | Slit Black | 29.0×34.5 | 55 | 120 | 0.103 | 25 |

| WY-UFW-PA6/S-AD42.5B | Slit Black | 36.0×42.5 | 65 | 150 | 0.153 | 25 |

| WY-UFW-PA6/S-AD54.5B | Slit Black | 48.0×54.5 | 80 | 190 | 0.209 | 25 |

WY-UFW-FPA6

| Materia | Polyamide 6 |

| Color | Gray (RAL 7037), nigrum (RAL 9005) |

| Temperature Range | Min-40℃,Max125℃, |

| Retardantia flammea | V0(UL94), se exstinguere, A libella, secundum FMVSS 302 .requisita, secundum GB/T2408 vexillum, flamma retardat ad planum V0 |

| Properties | Lenta et praeclara tenacitas, paries crassitudinis mediae, nitidumSuperficies, venti resistentes, vires mechanicae altae, repugnant oleo, acido et alcali. Anti-friction, nigrum Tubingae repugnant UV, Free Halogen, phosphoro et cadmia, transierunt RoHS. Ultra plana interior foramen, minus abrasio ad retinacula |

| Applications | Mechanica aedificium, electricum tutelae velit, sub terra, electricum vehiculum et aer-conditionalis apparatum etc.Maxime apta vehiculum industria crebris vibrationibus |

| fit cum | Omnes connexiones Tubing praeter WYTC apertum connexiones |

Tech Specification

| Articulus nullus. | Color | ID×OD | Stat.R | Dyn.R | Pondus | PU |

| WY-UFW-FPA6 | G/B | (mm×mm) | (mm) | (mm) | Dyn.r(mm) | (kg/m±10%) |

| *WY-UFW-FPA6-AD8.0G | Gray | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| *WY-UFW-FPA6-AD10.0G | Gray | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-UFW-FPA6-AD13.0G | Gray | 9.2×13.0 | 20 | 45 | 0.023 | 100 |

| WY-UFW-FPA6-AD15.8G | Gray | 12.0×15.8 | 25 | 55 | 0.034 | 100 |

| WY-UFW-FPA6-AD18.5G | Gray | 14.3×18.5 | 35 | 65 | 0.041 | 50 |

| WY-UFW-FPA6-AD21.2G | Gray | 16.0×21.2 | 40 | 75 | 0.093 | 50 |

| WY-UFW-FPA6-AD25.5G | Gray | 19.5×25.5 | 42 | 85 | 0.093 | 50 |

| WY-UFW-FPA6-AD28.5G | Gray | 22.2×28.5 | 45 | 100 | 0.093 | 50 |

| WY-UFW-FPA6-AD31.5G | Gray | 25.0×31.5 | 50 | 110 | 0.099 | 25 |

| *WY-UFW-FPA6-AD34.5G | Gray | 29.0×34.5 | 55 | 120 | 0.113 | 25 |

| *WY-UFW-FPA6-AD42.5G | Gray | 36.0×42.5 | 65 | 150 | 0.167 | 25 |

| *WY-UFW-FPA6-AD54.5G | Gray | 48.0×54.5 | 80 | 190 | 0.238 | 25 |

| WY-UFW-FPA6-AD8.0B | Niger | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-UFW-FPA6-AD10.0B | Niger | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-UFW-FPA6-AD13.0B | Niger | 9.2×13.0 | 20 | 45 | 0.023 | 100 |

| WY-UFW-FPA6-AD15.8B | Niger | 12.0×15.8 | 25 | 55 | 0.034 | 100 |

| WY-UFW-FPA6-AD18.5B | Niger | 14.3×18.5 | 35 | 65 | 0.041 | 50 |

| WY-UFW-FPA6-AD21.2B | Niger | 16.0×21.2 | 40 | 75 | 0.093 | 50 |

| WY-UFW-FPA6-AD25.5B | Niger | 19.5×25.5 | 42 | 85 | 0.093 | 50 |

| WY-UFW-FPA6-AD28.5B | Niger | 22.2×28.5 | 45 | 100 | 0.093 | 50 |

| WY-UFW-FPA6-AD31.5B | Niger | 25.0×31.5 | 50 | 110 | 0.099 | 25 |

| WY-UFW-FPA6-AD34.5B | Niger | 29.0×34.5 | 55 | 120 | 0.113 | 25 |

| WY-UFW-FPA6-AD42.5B | Niger | 36.0×42.5 | 65 | 150 | 0.167 | 25 |

| WY-UFW-FPA6-AD54.5B | Niger | 48.0×54.5 | 80 | 190 | 0.238 | 25 |

| WY-UFW-FPA6/S-AD8.0B | Slit Black | 5.7×8.1 | 12 | 30 | 0.008 | 200 |

| WY-UFW-FPA6/S-AD13.0B | Slit Black | 6.5×10.0 | 15 | 35 | 0.014 | 100 |

| WY-UFW-FPA6/S-AD10.0B | Slit Black | 9.2×13.0 | 20 | 45 | 0.023 | 100 |

| WY-UFW-FPA6/S-AD15.8B | Slit Black | 12.0×15.8 | 25 | 55 | 0.034 | 100 |

| WY-UFW-FPA6/S-AD18.5B | Slit Black | 14.3×18.5 | 35 | 65 | 0.041 | 50 |

| WY-UFW-FPA6/S-AD21.2B | Slit Black | 16.0×21.2 | 40 | 75 | 0.093 | 50 |

| WY-UFW-FPA6/S-AD25.5B | Slit Black | 19.5×25.5 | 42 | 85 | 0.093 | 50 |

| WY-UFW-FPA6/S-AD31.5B | Slit Black | 22.2×28.5 | 45 | 100 | 0.093 | 50 |

| WY-UFW-FPA6/S-AD28.5B | Slit Black | 25.0×31.5 | 50 | 110 | 0.099 | 25 |

| WY-UFW-FPA6/S-AD34.5B | Slit Black | 29.0×34.5 | 55 | 120 | 0.113 | 25 |

| WY-UFW-FPA6/S-AD42.5B | Slit Black | 36.0×42.5 | 65 | 150 | 0.167 | 25 |

| WY-UFW-FPA6/S-AD54.5B | Slit Black | 48.0×54.5 | 80 | 190 | 0.238 | 25 |

Institutiones de Polyamide Tubing

Propellente Tubing in iungo et conventu suo facto. Detrudere iterum donec suam definitionem complere non possit, ut ad aliquem gradum tutelae pervenire possit.

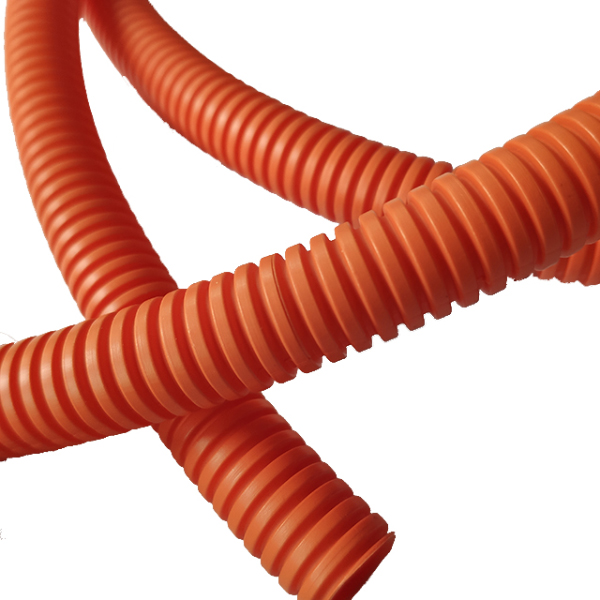

Normalis undam

Ultra plana fluctus

Tubing non rumpitur

Slit Tubing

commoda Flexibilis Polyamide Conduit

1. Excelsa vis mechanica, durities bona, alta fortitudo distrahens et compressiva.

2. Labor resistentia praestantior est, partesque pristinas vires mechanicas post iteratam inclinationem adhuc conservare possunt.

3. Summum punctum emolliens et calor resistens.

4. Superficies levis est, attritio coefficientis parva est, et obsistente est.

5. Corrosio resistendi.

6. Exstinguere, non noxia, inodora.

7. Praeclara electrica proprietates, bonae electricae insulae.

Pictures of Polyamide Tubing Corrugated

Applicationem PolyamideTubing: Machina aedificium

Infra imagines communicamus pro applicatione in una e nostris in machinationibus emptoris. Funes sub IP68 vel IP69K protegi debent contra aquam et pulverem, cum egreditur e archa potestate, quae vitam funis usus extendere potest.